Brushed DC Motors

ISL Products manufactures and supplies an array of value-added brushed dc motors based on your design specifications. Our brushed dc motors have been tested in the harshest industrial environmental conditions, making them a reliable, cost-sensitive and simple solution for any application. Our team of engineers will review your brushed dc motor requirements and work to provide a solution based on your application.

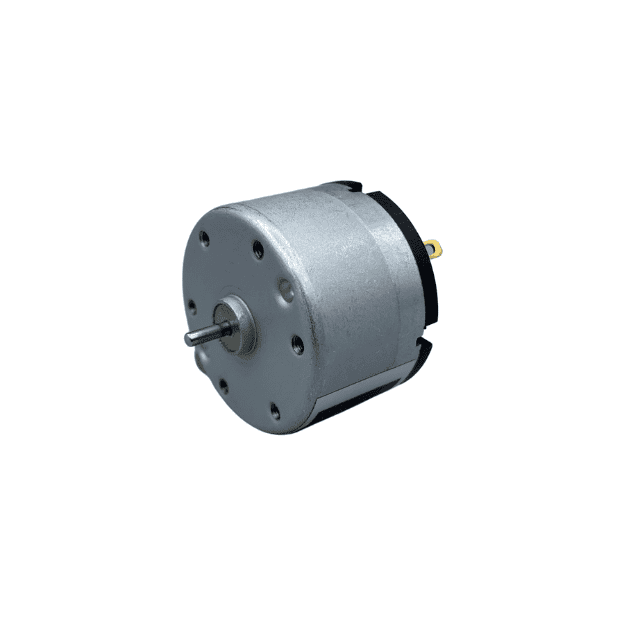

Our dc motors are a cost-effective solution when standard AC power is not accessible or needed. They feature an electromagnetic rotor and a stator with permanent magnets. The industry-wide compatibility of an ISL brushed dc motor makes integration into your application effortless. You can choose one of our standard options or consult with an application engineer for a more tailored solution.

Shop Popular Models

What are brushed motors?

A brushed DC permanent magnet electric motor generates motion by running direct current through an armature winding coil attached to the motor’s rotor. This current creates a magnetic field that attracts and repels permanent magnets attached to the stator. Every half turn the commutator reverses the direction of the current, making the magnetic field reverse, forcing the motor to make another half rotation. This interaction creates continuous rotation that is perfect for a wide range of applications. In broader terms, a motor converts electrical energy into mechanical energy.

Brushed motors are popular for their simplicity. Unlike brushless dc motors (BLDC Motors) that need a specialty controller, a standard dc electric motor has two terminals, a positive and negative. The dc electric motor is driven by applying voltage directly to the terminals. The direction of rotation can be reversed by reversing the wiring polarity on the motor’s terminals. This makes brushed motors easy to integrate into any application. Brushed DC motor controllers are used for speed control when needed, while being rather simplistic.

A Solution for Any Application

ISL offers motors in a wide range of sizes, from the mini electric hobby motor to micro-gear motors to the larger worm gear motors found inside of pallet jacks. Brushed motors are frequently paired with a spur gearbox or planetary gearboxes for increased torque. It’s important to know your on load torque and stall torque requirements to determine if a gearbox is required. Typically, smaller dc motors will have a rated supply voltage of 3V ~6V and larger size motors will operate at a voltage of 12V – 48V, with 12V and 24V being the most widely utilized.

For more sophisticated applications where you need full control of speed, there are simple brushed dc motor controllers that can be used. We can offer unique value-added options for applications where electrical noise (EMI) is a concern. When using a battery as a power source, the motor’s current consumption will become a key factor in determining your useful battery life. Their simplicity results in lower price-tags, making brushed motors an economical choice for a wide variety of devices.

ISL Products superior motors results in high torque density, superior performance and a value-added motor provides you with the optimal solution. Contact our team of design engineers today to learn more about our dc motor product offering.

Popular Models Available:

MOT-I-81567-A / BDC-N36-57-24-5000-S – This model is 38mm in diameter with a no-load speed of 5,000 rpm. Rated operating conditions: 24VDC / 4,300 rpm / 274 g.cm / 725 mA.

MOT-I-81567-B / BDC-H33-22.7-12-6000-S – This model is 33mm in diameter with a no-load speed of 6,000 rpm. Rated operating conditions: 12VDC / 5,000 rpm / 35 g.cm / 230 mA.

MOT-52MM MOTOR24V / BDC-N52-69-24-2000-S – This model is 52mm in diameter with a no-load speed of 2,000 rpm. Rated operating conditions: 24VDC / 1,500 rpm / 490 g.cm / 600 mA.

Brushed DC Motors FAQ's

-

Choosing between a DC and an AC motor depends on the specific requirements of the application. While AC motors are generally more efficient and low-maintenance, DC motors offer simpler speed control and are often more cost-effective in certain applications where standard AC power is not accessible or needed. When deciding which motor type is better, it is important to consider factors such as power source availability, speed control requirements, and overall cost-effectiveness in the intended application.